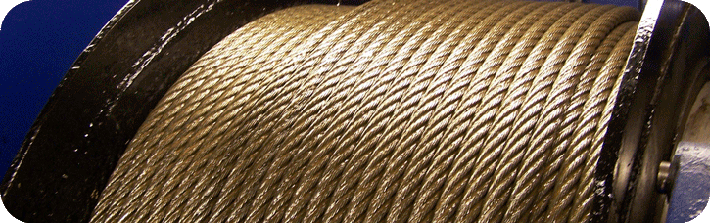

Correct lubrication of wire ropes, chains and cables will safely increase their operational life. Applications such as cranes, drilling rigs, shovels, draglines and suspension bridges all use wire rope, chain or cable to perform work such as pulling or hoisting. Extreme environmental conditions are common, and the correct use of LE’s high-performance Wirelife® lubricants will provide safely extended life to wire ropes, chains and cables.

Wire ropes need protection from the inside out

Most wire ropes fail from the inside out. When selecting an effective wire rope lubricant, choose products that are free of acids and alkalis, possess the adhesive strength to stay on the rope, are able to penetrate between wires and strands, have high fluid film strength, resist oxidation and remain pliable.

Corroded rope can be a safety hazard, as there is no way to determine its remaining strength and life. Proper lubrication will help prevent wire rope deterioration due to rust and corrosion. LE has a range of penetrating and coating type wire rope lubricants to suit specific applications.

Penetrating lubricants

Penetrating lubricants contain a petroleum solvent that carries the lubricant into the core of the wire rope, then evaporates, leaving behind a heavy lubricating film to protect and lubricate each strand. A penetrating lubricant is critical as most wire rope fails from the inside out.

Coating lubricants

Coating lubricants penetrate slightly while sealing the outside of the wire rope from moisture, and reducing wearing and fretting corrosion. For a coating lubricant, it is best practice to first use a penetrating lubricant to saturate the c ore. After the penetrating product has dried, apply the coating lubricant to seal and protect the outside of the wire rope.

Environmentally friendly lubricants

LE has an environmentally friendly Wirelife® Low Tox® penetrating lubricant, which is important if the wire rope lubricant is used in aquatic or other environmentally sensitive areas. During relubrication, wash-off due to environmental exposure or lubricant degradation can cause the wire rope lubricant to enter the surrounding ecosystem. LE’s Low Tox lubricant is inherently biodegradable, which means the majority of the product biodegrades over time. It has up to a tenfold reduction in toxicity impact in comparison to traditional lubricants.

LE can also provide the following value-added options:

- Lubrication education and training

- Viper Wire Rope Lubricator

View Product Details: